The Risks of Static Supply Chains in a Dynamic World

In an era of unprecedented technological advancement and global interconnectedness, the business landscape is marked by relentless change and disruption. Yet, many organizations remain tethered to static supply chains, an approach that increasingly jeopardizes their adaptability, profitability, and long-term viability.

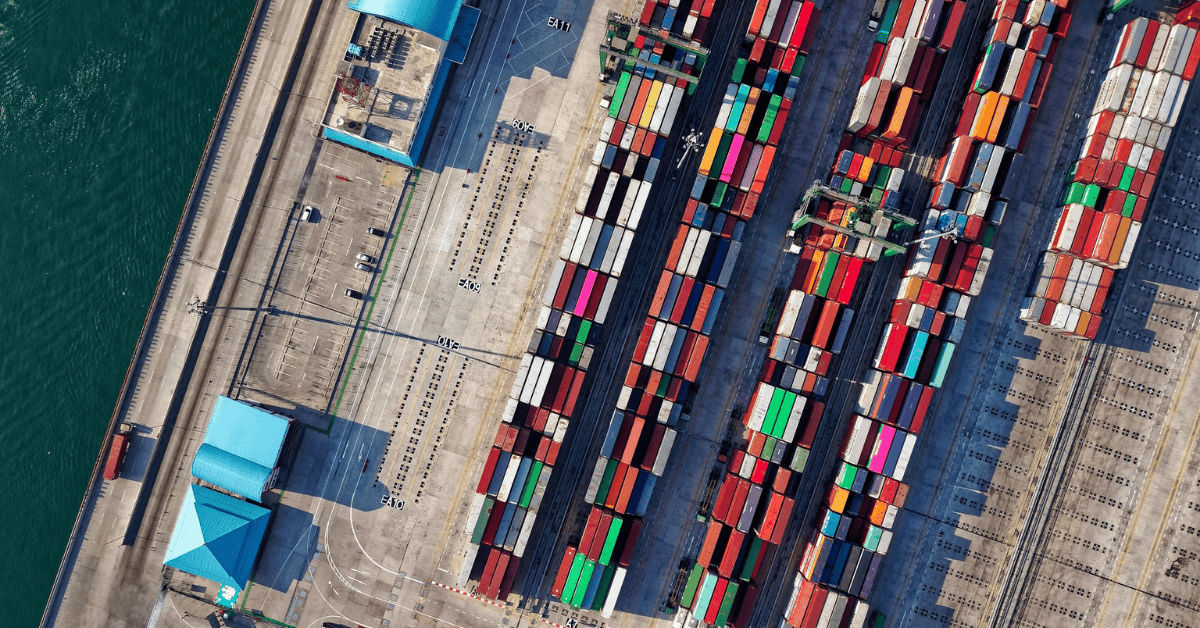

The COVID-19 pandemic served as a stark wake-up call, exposing the brittleness of these traditional supply chains. Lockdowns, factory closures, and transportation disruptions triggered widespread disruptions, exposing vulnerabilities and bottlenecks throughout global supply chains. This global crisis underscored the limitations of rigid, linear supply chain models that struggle to adapt to sudden shifts in demand, unforeseen disruptions, and volatile market conditions. The pandemic highlighted the urgent need for agility, flexibility, and, above all, supply chain resilience—attributes that static models inherently lack.

What is a Supply Chain Risk?

A supply chain risk encompasses any potential event or condition that could disrupt, delay, or damage the seamless flow of goods, services, or information within a supply chain, ultimately impacting business operations. Effective supply chain risk management entails understanding these potential disruptions and proactively implementing strategies to mitigate their impact. These risks can originate from various sources and can have significant consequences for businesses, including:

- Financial losses: Increased costs, lost sales, and decreased profitability.

- Operational disruptions: Delays in production, missed deadlines, and customer dissatisfaction.

- Reputational damage: Loss of trust, negative publicity, and diminished brand value.

- Legal and regulatory issues: Fines, penalties, and lawsuits.

Types of Supply Chain Risks

Supply chain risks can be broadly categorized into the following types:

- Internal Risks: These risks arise from factors within a company’s control, such as production delays, quality issues, inventory shortages, labor strikes, and IT system failures.

- External Risks: These risks originate from factors outside a company’s control, such as natural disasters, geopolitical events, economic downturns, supplier bankruptcies, transportation disruptions, and pandemics.

- Demand Risks: These risks are related to fluctuations in customer demand, inaccurate forecasting, product obsolescence, and changing market trends.

- Supply Risks: These risks stem from supplier-related issues, such as raw material shortages, supplier financial instability, quality problems, and logistical challenges.

- Environmental Risks: These risks are associated with climate change, natural disasters, pollution, and resource scarcity.

- Regulatory Risks: These risks are related to changes in laws, regulations, trade policies, and tariffs.

- Cybersecurity Risks: These risks involve cyberattacks, data breaches, ransomware attacks, and other digital threats that can disrupt supply chain operations.

Supply Chain Risk Statistics

According to Gartner, supply chain leaders are increasingly concerned about the growing complexity and volatility of risks. Their research indicates that:

- 75% of companies experienced some form of supply chain disruption in the past two years.

- 47% of companies reported a significant financial impact from these disruptions.

- Only 21% of companies feel they have a highly resilient supply chain.

These statistics highlight the urgent need for organizations to proactively assess supply chain risks and build resilience into their operations.

The Anatomy of a Static Supply Chain

A static supply chain is characterized by rigid processes, linear structures, and limited adaptability. It operates on the assumption of predictable demand, stable markets, and unwavering supplier relationships. While this model may have sufficed in a bygone era of relative stability, it is increasingly out of sync with today’s reality.

The Risks of Inertia

- Vulnerability to Disruptions: The COVID-19 pandemic highlighted the inherent vulnerability of static supply chains. Unexpected events, whether natural disasters, geopolitical instability, or economic shifts, can easily trigger supply chain disruptions in these linear models. A single point of failure, such as a supplier shutting down or a port closure, can cascade throughout the chain, causing significant delays, shortages, and financial losses.

- Missed Opportunities: In the fast-paced global market, consumer preferences, technological advancements, and regulatory landscapes are constantly evolving. Static supply chains are slow to respond to these changes, hindering a company’s ability to innovate, meet emerging demands, and seize new market opportunities. The lack of agility leaves businesses trailing behind more adaptable competitors who can quickly pivot and capitalize on emerging trends.

- Inefficiencies and Cost Overruns: The rigid nature of static supply chains often leads to operational inefficiencies. Manual processes, fragmented communication channels, and outdated technology hinder the flow of information, resulting in inventory imbalances, production bottlenecks, and unnecessary costs. These inefficiencies can erode profit margins and decrease overall competitiveness.

- Environmental and Social Impact: Traditional, linear supply chains are often associated with unsustainable practices. They rely on resource extraction, generate significant waste, and contribute to environmental degradation. Moreover, they may lack transparency and fail to address social issues such as fair labor practices and human rights. In an era where consumers increasingly prioritize sustainability and ethical sourcing, these shortcomings can damage a company’s reputation and alienate customers.

The Case for Dynamic Supply Chains

In contrast to their static counterparts, dynamic supply chains are designed for agility, flexibility, and responsiveness. They leverage technology, data analytics, and collaboration to adapt to changing conditions, mitigate risks, and seize opportunities.

The Benefits of Agility

- Enhanced Resilience: Dynamic supply chains are more resilient to disruptions due to their ability to quickly identify and respond to potential threats. They utilize real-time data and predictive analytics to anticipate risks, diversify suppliers, create redundancies, and develop contingency plans. This proactive approach minimizes the impact of disruptions, ensuring business continuity and protecting the bottom line.

- Improved Responsiveness: By leveraging advanced technologies such as artificial intelligence, machine learning, and blockchain, dynamic supply chains can gather and analyze vast amounts of data in real-time. This enables them to anticipate customer demand, detect emerging trends, and respond quickly to market shifts. The ability to pivot and adapt to changing circumstances provides a significant competitive advantage.

- Increased Efficiency: Dynamic supply chains optimize operations through automation, digitization, and data-driven decision-making. Automated processes reduce manual errors and free up resources, while digital platforms facilitate seamless communication and collaboration across the entire supply chain network. Data-driven insights help identify bottlenecks, streamline processes, and improve overall efficiency, leading to cost savings and increased profitability.

- Sustainable Practices: Dynamic supply chains can integrate sustainability principles throughout their operations. By incorporating circular economy models, reducing waste, and optimizing resource utilization, they can minimize their environmental footprint. They can also prioritize ethical sourcing, fair labor practices, and social responsibility, enhancing their brand image and attracting conscientious consumers.

Navigating the Path to a Dynamic Supply Chain Future

Transforming a static supply chain into a dynamic one is a journey of evolution, not revolution. It requires a strategic approach that seamlessly integrates technology, processes, people, and culture.

Technology acts as the backbone, providing the tools for real-time visibility and data-driven insights that empower informed decision-making. Processes are reimagined for agility, allowing the supply chain to adapt and respond swiftly to fluctuations in demand or unforeseen disruptions.

However, the true driving force behind this evolution is the people. By investing in their skills and nurturing a collaborative, innovative culture, businesses unlock the human potential that fuels a dynamic supply chain. This cultural shift, where adaptability and continuous improvement are embraced, creates a resilient, responsive, and efficient ecosystem that thrives in the face of change.

Embarking on this evolutionary journey may seem daunting, but the rewards are undeniable: a supply chain that is not merely functional, but a strategic asset that drives growth and competitive advantage.

Identifying and Assessing Supply Chain Risks

A critical first step in building a resilient and dynamic supply chain is to proactively identify and assess potential risks. This involves a thorough examination of your entire supply chain network, from raw material sourcing to final product delivery. By understanding your vulnerabilities, you can take targeted action to mitigate risks and strengthen your overall resilience. Here are some key steps to consider:

Conduct a Comprehensive Risk Assessment

Start by mapping out your entire supply chain, identifying all the critical nodes, dependencies, and potential risk factors. Consider both internal factors (such as operational processes and resource availability) and external factors (such as geopolitical events and natural disasters).

Categorize Risks

Once you have identified potential risks, categorize them based on their likelihood and potential impact. This will help you prioritize your risk mitigation efforts.

Utilize Risk Assessment Tools

Various risk assessment tools and methodologies are available to help you quantify and prioritize risks. These tools can provide valuable insights into your supply chain’s vulnerabilities and help you develop effective mitigation strategies.

Engage Stakeholders

Involve key stakeholders from across your organization and supply chain network in the risk assessment process. This will ensure that you have a comprehensive understanding of all potential risks and can develop collaborative solutions.

Continuously Monitor and Update

Risk assessment is not a one-time activity. It’s an ongoing process that requires continuous monitoring and updating as conditions change. Regularly review your risk assessment to ensure that it remains relevant and reflects the latest developments in your industry and global landscape.

Strategies for Building a Dynamic Supply Chain

- Embrace Digital Transformation: Invest in advanced technologies such as artificial intelligence, machine learning, blockchain, and the Internet of Things to enhance visibility, optimize processes, and enable data-driven decision-making.

- Foster Collaboration: Break down silos and foster collaboration across departments, suppliers, and partners to improve communication, coordination, and responsiveness.

- Develop Agile Processes: Implement agile methodologies to enable rapid response to change, continuous improvement, and experimentation.

- Invest in Talent: Develop the skills and capabilities of your workforce to leverage new technologies, manage complex data, and navigate a dynamic business environment.

- Build a Culture of Continuous Improvement: Encourage a mindset of continuous learning, experimentation, and innovation to stay ahead of the curve and adapt to the ever-changing business landscape.

Unlock Your Supply Chain’s Potential with Armstrong

The transition to a dynamic supply chain is not just an option—it’s a necessity for survival and growth in today’s volatile business landscape. Static models are fraught with risks, from disruptions and missed opportunities to inefficiencies and unsustainable practices. Embracing agility, fueled by technology, collaboration, and a commitment to continuous improvement, is the key to building resilience, responsiveness, and efficiency. BBF Global Logistics has joined The Armstrong Company, enhancing their combined capabilities to adapt swiftly to market changes and deliver superior supply chain solutions.

This journey can be complex, but Armstrong is here to guide you. Our comprehensive suite of supply chain solutions, from cutting-edge technology to expert consulting, empowers businesses to effectively manage supply chain risks and navigate the path to supply chain excellence. By partnering with Armstrong, you can transform your supply chain into a strategic asset that drives growth and propels your business forward in the face of any challenge. Contact Armstrong today and discover how we can help you unlock your full potential.